Customer industry: Bearing industry

Cutting equipment: Han Hong circular saw machine

Cutting material: GCr15 bearing steel (not annealed)

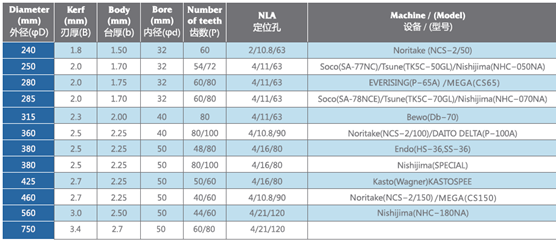

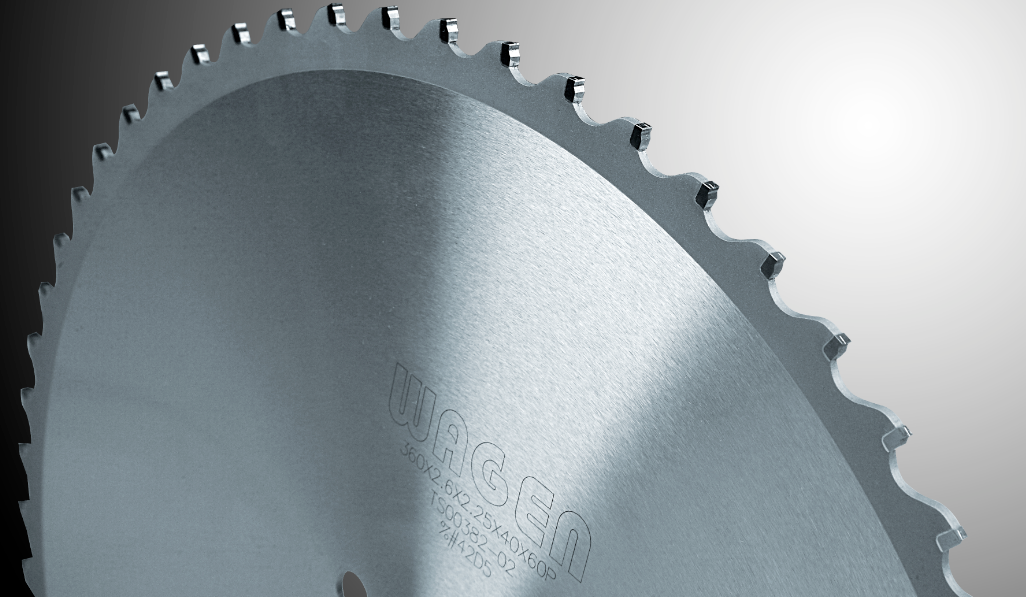

WST-MSaw blade type: cold saw series WST-M

As is known to all, GCr15 (unannealed) material is a kind of steel which is difficult to cut, and the requirements for cutting saw blades are very high.The most common problem encountered by many users is that the service life of the saw blade is not long, which leads to the increase of the cost in the later period.

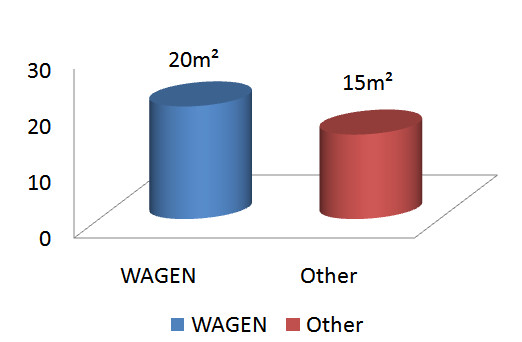

The customer from Dalian China previously used other Japanese brand, that cutting life is about 15m, plus high replacement frequency ,can notreach the ideal cutting life, which virtually increases the use cost.

WAGEN’s senior technical engineers went to the scene for checking, according to the use of equipment and materials, found the key to cutting problem is on the teeth, and decided to try the upgrade version of the WST - M cold saw blade saw, through a series of debugging, the final cutting life reaches around 20 M squared, and the cut surface is smooth, customers satisfied on it.

Comparition of life data

Cutting material: GCr15 130 unannealed material

GCr15 150 unannealed material

Cutting parameters: rotate speed68

Feeding speed:0.035-0.037

About cold saw blade WST-M

WST-M adopts all-imported new super durable and wear-resisting cermetmaterial, with unique anti-seismic patented design, which improves the stability of the saw blade and extends its service life.Suitable for cutting medium and low carbon steel, excellent cutting surface, reduce the following operation cost;High precision cutting performance and product cost performance improvement.

Common cutting parameters