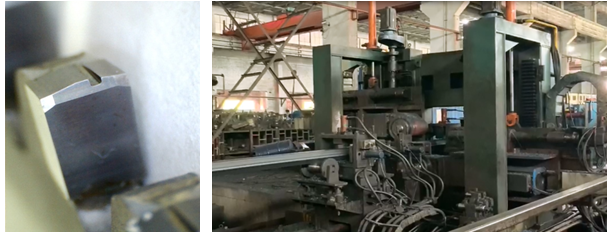

Recently, Wagen brings out flying sawblade---WST-SR, which is able to cut steel tube with higher hardness. The material of teeth and body are provided by the first-class foreign manufacturers, and teeth material is carbide, processed with coating; Flying sawblade---WST-SR is used to cut tube that material is carbon steel

up to 0.4% carbon and alloy steel, like welding tube and drawing tube. Applied on copy milling flying saw cutting machine and high precision metal cutting machine,etc.

Product Advantage

Reliability of raw material quality

The tip and base materials used by WAGEN flying saw products are all provided by the first-class foreign manufacturers in the industry to ensure the stability and reliability of the saw blade material.

Controllability of process quality

As a first-class saw blade production enterprise, we have a complete saw blade production and processing system. Whether the substrate heat treatment or the saw blade coating, our company can effectively ensure the production schedule and quality control.

Flying saw products adopt various special saw blade teeth design to meet the processing needs of different customers.At the same time, with an independent coating workshop and unique coating process,we can satisfied the cutting quality and service life requirements of the saw blade.

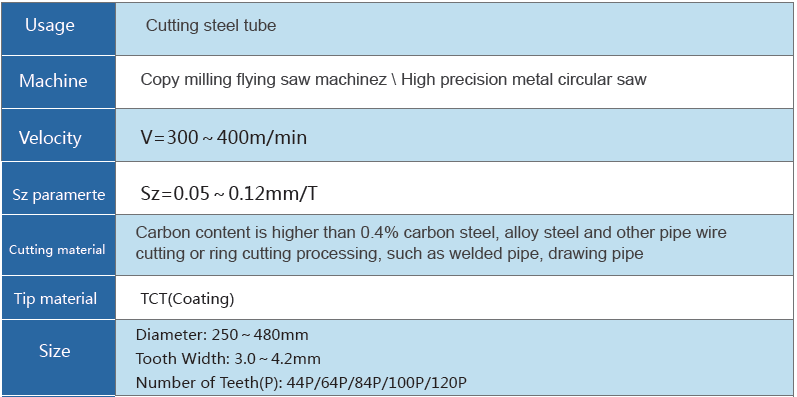

Production information

Product performacne

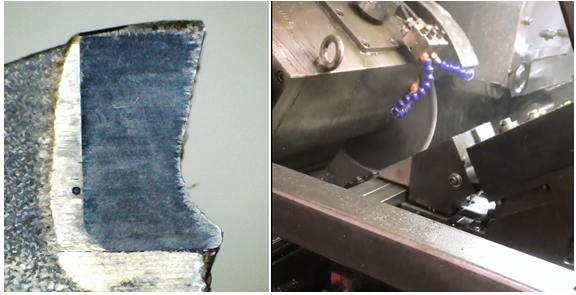

Customer from Hebei province(China)

Cutting materials: tensile strength 900MPa or above pipe

Machine:High speed circular saw machine, emulsion cutting

Aim:No burr, cutting life required about 5500 knives

Test life: cutting quantity is about 6000 knives to meet customer's needs.

Customers from JiangSu province(China)

Cutting materials: Tensile strength 400~600 welded pipe and tensile strength 600~800 welded pipe

Machine: Copy milling flying saw machine, oil mist cutting and emulsion cutting each one group

Aim: No burr, cutting life required about 8000~10000 knives

Test life: Batch FYM1240, cutting quantity is about 7500~8800 knives.

Customer from Shanghai(China)

Cutting materials: Tensile strength 400~600 welded pipe and tensile strength 600~800 welded pipe, two pieces cutting together.

Machine: Copy milling flying saw machine, emulsion cooling

Aim: No raw edge, new one life request 1.5㎡, and life request 1㎡ after repair, 2 pieces cutting together

Test life: Test life 1.8 square meters, cut 1.2 square meters after repair.